Page 44 - Microsoft Word -Cow Book 10-06-09 final update.doc

P. 44

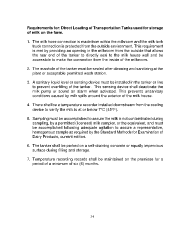

Requirements for: Direct Loading of Transportation Tanks used for storage

of milk on the farm.

1. The milk hose connection is made from within the milkroom and the milk tank

truck connection is protected from the outside environment. This requirement

is met by providing an opening in the milkroom from the outside that allows

the rear end of the tanker to directly seal to the milk house wall and be

accessible to make the connection from the inside of the milkroom.

2. The manhole of the tanker must be sealed after cleaning and sanitizing at the

plant or acceptable permitted wash station.

3. A sanitary liquid level or sensing device must be installed in the tanker or line

to prevent overfilling of the tanker. This sensing device shall deactivate the

milk pump or sound an alarm when activated. This prevents unsanitary

conditions caused by milk spills around the exterior of the milk house.

4. There shall be a temperature recorder installed downstream from the cooling

device to verify the milk is at or below 7C (45F).

5. Sampling must be accomplished to assure the milk is not contaminated during

sampling, by a permitted (licensed) milk sampler, or the equivalent, and must

be accomplished following adequate agitation to assure a representative,

homogenous sample as required by the Standard Methods for Examination of

Dairy Products, current edition.

6. The tanker shall be parked on a self-draining concrete or equally impervious

surface during filling and storage.

7. Temperature recording records shall be maintained on the premises for a

period of a minimum of six (6) months.

34